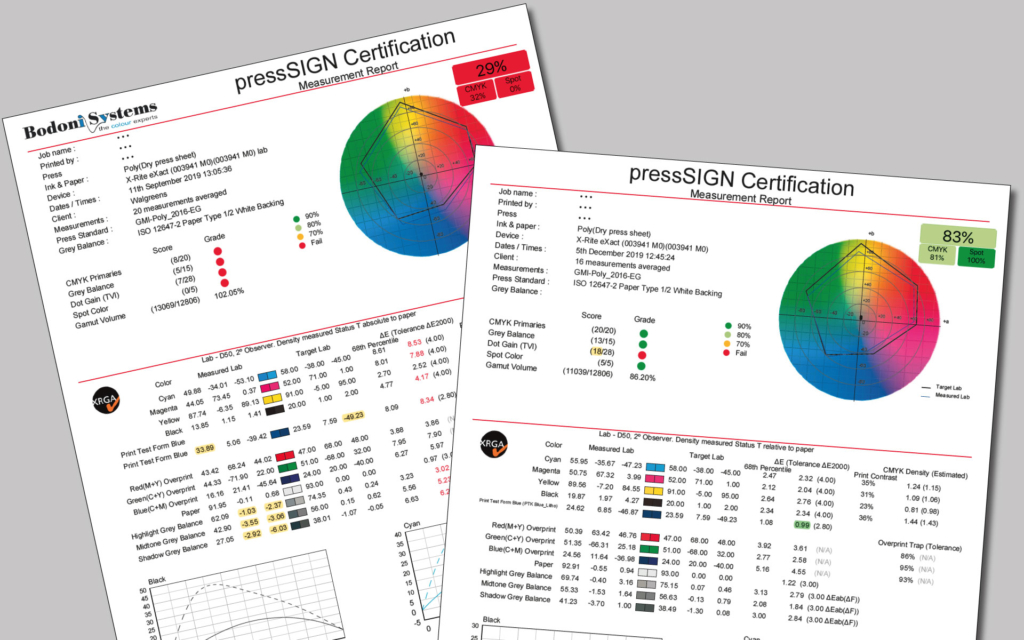

Here is a print condition audit that initially revealed an insufficient quality level, scoring below 30%, and ended with a final score of 83% with satisfaction of both printer and final customer.

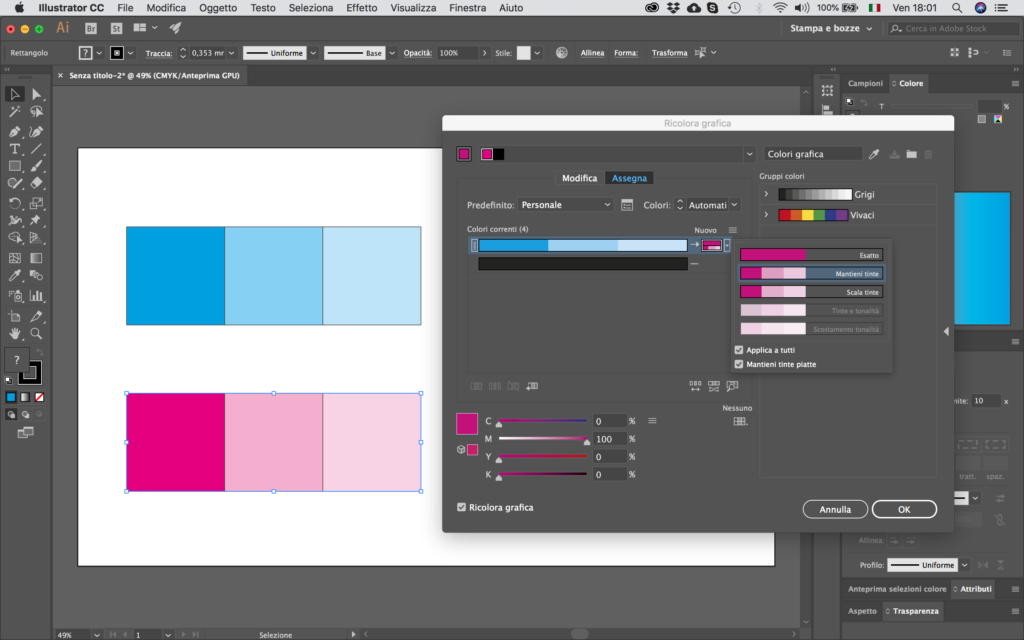

The printer invested in 3 days of process calibration activities over 3 weeks time with the limitation of using the existing press setup (anilox rolls, plate, cushion, inks):

- Day 1: optimisation on single colors to determine ink transfer characteristics with different plate surface textures, dot gain compensation and minimum dot settings for the desired print linescreen.

- Day 2: fingerprint in full color (CMYK + Spot + White) to check and confirm screening settings and get values for grey balance.

- Day 3: characterisation (CMYK + Spot + White) to confirm all settings are ok and measure characterisation data.

Simple, ain’t it?