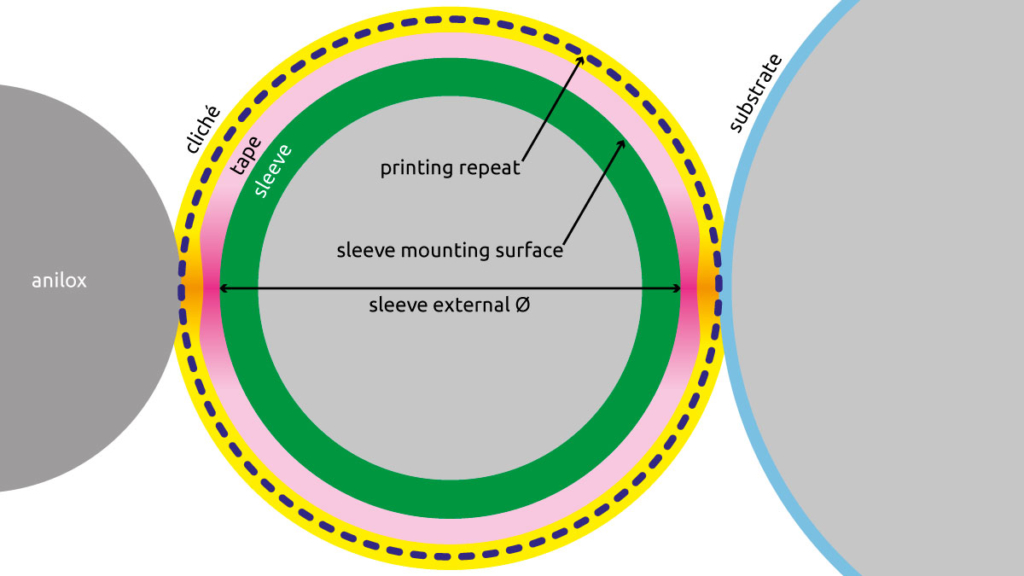

It is important to know in depth the technical characteristics of the printing press, and especially the configuration of the cylinders. Their diameters, combined with the gauge and the resilience of the plate, of the mounting tape and of the substrate, will determine whether the print will happen in the right position, without slurring, having the surface of the plate running in synchronous with the substrate and the anilox roll.

Since the design of the anilox roll (its external Ø) and the position of the substrate are determined by the press manufacturer parameters, the most important component, left to the control of the user, is the external diameter of the sleeve, also called mounting diameter.

We use to call flexography as “kiss printing” but there is actually a compression: print doesn’t happen without a minimum contact. So there is an interference between the the circumference of the outer surface of the plate and the circumferences of the anilox and substrate.

If we let this interference to be too high (say >150 µm), we risk that the surface of the plate runs too much outside the printing circumference diameter so when touching the substrate (or the anilox) it will slur running faster.

If we let this interference to be zero, or lower than 20 µm, we risk that the print impression happens below the circumference of the printing repeat: the impression will be found when the surface of the plate runs slower than the surface of the substrate or the anilox, slurring.

| Example (metric) for repeat 500 mm |

Example (imperial) for repeat 20 inch |

|

|---|---|---|

| Plate thickness | 1,14 mm | 0.045″ |

| Tape thickness | 0,50 mm | 0.020″ |

| Compression | 50 µm | 2 thou |

| Printing repeat | 500 mm | 20″ |

| Printing Ø (¹) | 159,155 mm | 6.3662″ |

| Sleeve external Ø (²) | 155,975 mm | 6.2402″ |

(¹) Printing Ø = Printing repeat ÷ π

(²) Sleeve external Ø = Printing Ø − 2×(Plate + Tape – Compression)

Wrong interference settings will affect the followings:

- slur

- repeat length accuracy

- registration along the repeat

- matching with die-cutting

- ink build-up

- dot-gain