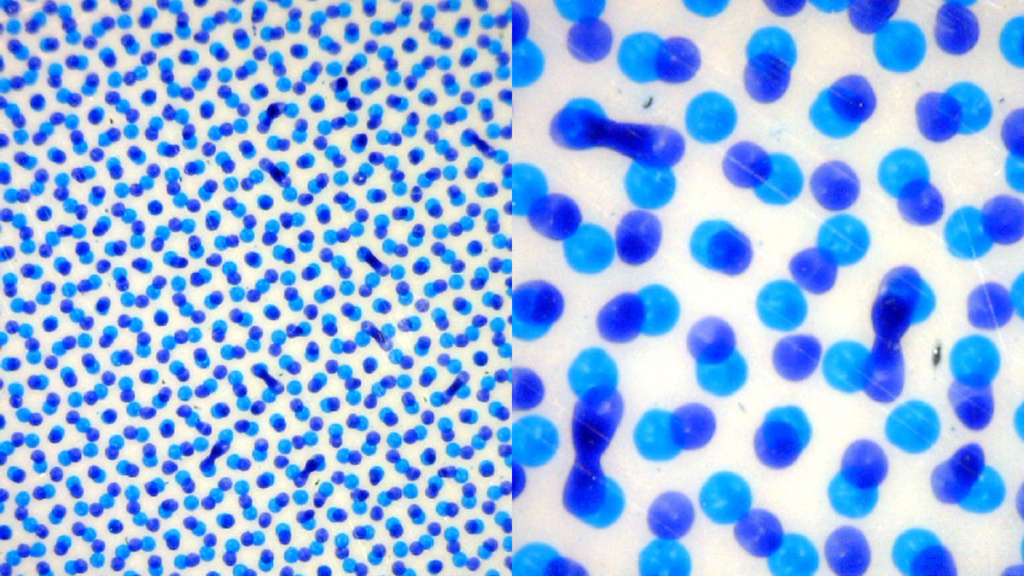

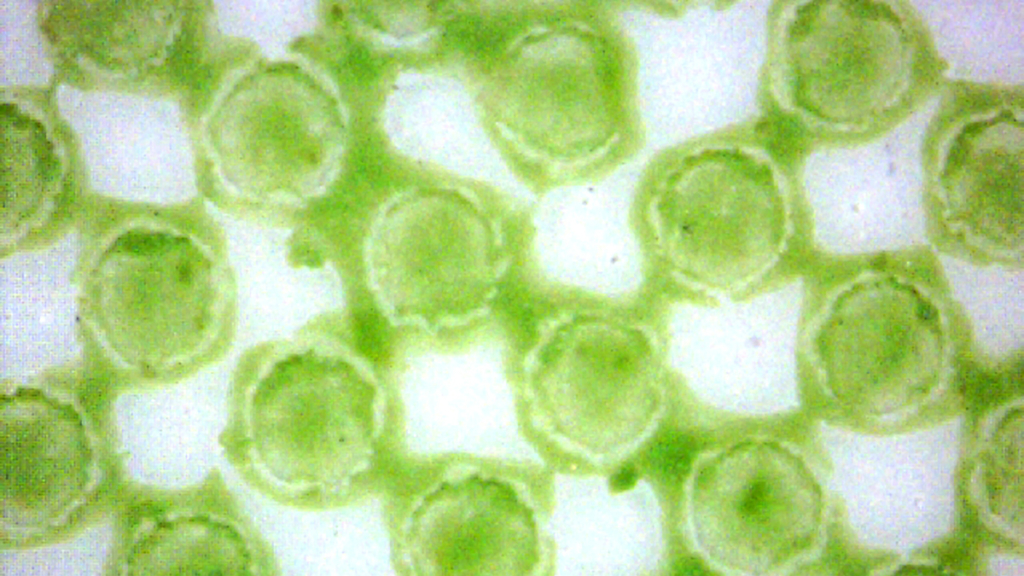

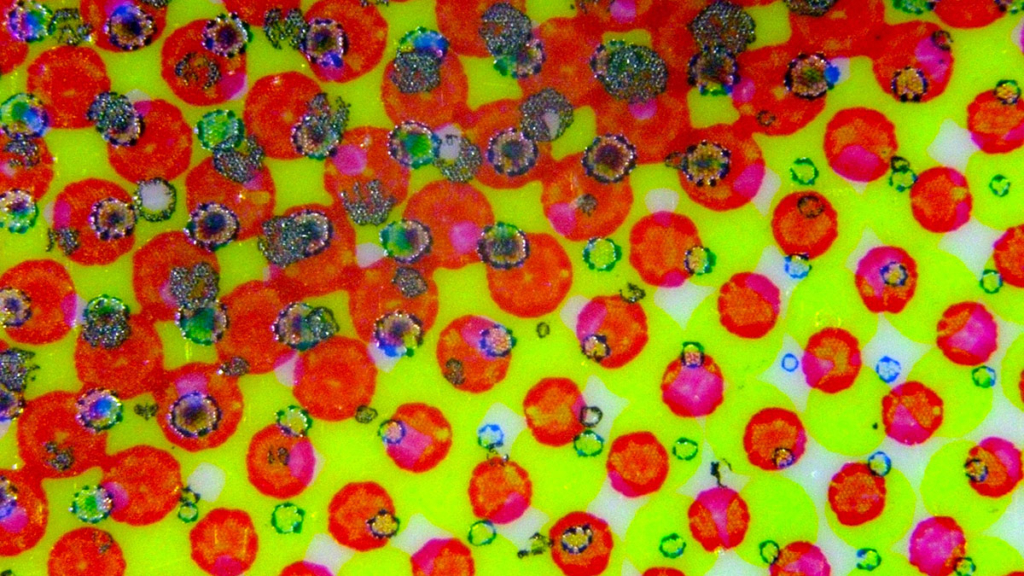

Dots in midtones screened areas, that normally should appear separated on printing, bridge together causing a dirty aspect on printed product.

Main addressable cause is anilox volume too high for the selected plate linescreen, or, viceversa, plate linescreen too high for the available anilox volume. The ink, collected by the printing surface of the plate dots from the anilox, is squeezed when touching the substrate and the droplets bridge together creating larger inked areas.

Other secondary causes might involve too high viscosity of the ink, or unsuitable ink, dirty particles on plate due to substrate dust (paper), excessive impression.

Reduce anilox volume or use printing plates with lower linescreen.

Check ink viscosity and suitability for application, clean the plate from eventual dust from substrate (paper), adjust (reduce) impressions both anilox/plate and plate/substrate.

hi Flexo expert.

we have a problem that we are not able to solve so far. so I would like to hear your opinion about it.

we print YMCK in an Allstein CI printing machine and having problem similar to bridging but it only occurs in the forefront of the printing area, same problem on all packages ( x 6 on the plate/print cylinder) only black ink having this problem and in a 15 % dot area.

we have checked everything we can think of: ink, solvent, plates, dryers, impression, anilox, sleeve, temperature and humidity (Pakistan).

we can run about 20 000 meters, with new plates, then we get the problem. we take out and wash cliché but after a 1000 meters it comes back. this is a big orders and we loose a lot of capacity.

please help us!

best regards

Hans Jönsson

Hello Hans, thank you for leaving a comment here. I will contact you via email so we can better explore the case.