Do you really think that dot dipping doesn’t exist?

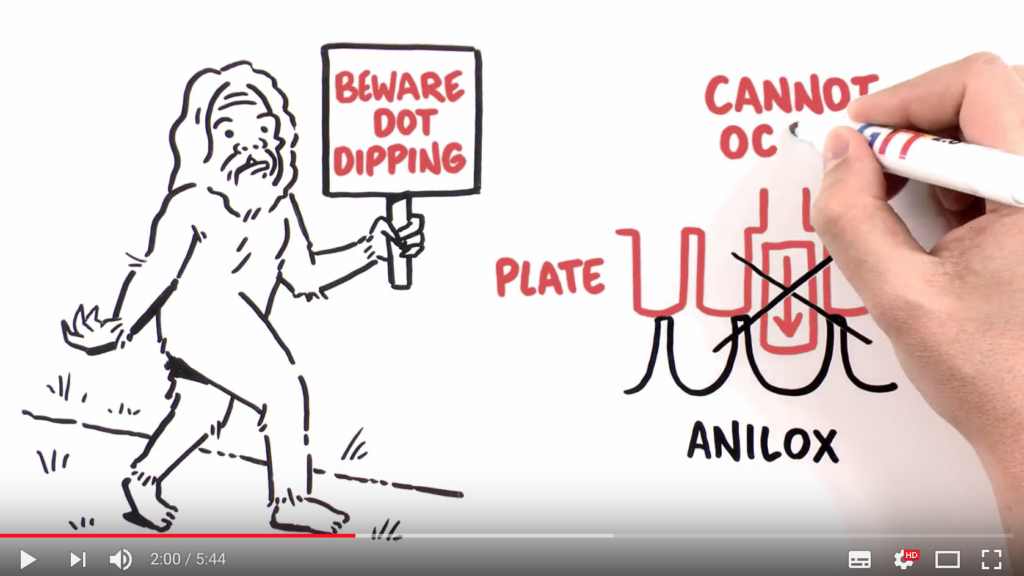

I recently came across an interesting video that was published by one anilox rolls manufacturer that, in the attempt of promoting their technology, depicts dot dipping as an industry myth and illustrates flexo users, who believe that this problem exists, as troglodytes… “The industry myth that dot dipping is occurring within the anilox cells is impossible. Physics […]

Do you really think that dot dipping doesn’t exist? Read More »