I recently came across an interesting video that was published by one anilox rolls manufacturer that, in the attempt of promoting their technology, depicts dot dipping as an industry myth and illustrates flexo users, who believe that this problem exists, as troglodytes…

“The industry myth that dot dipping is occurring within the anilox cells is impossible. Physics can prove that the amount of pressure required to force one plate dot to enter into an anilox cell, while the adjacent dot remains in contact with the anilox surface, simply cannot occur…”

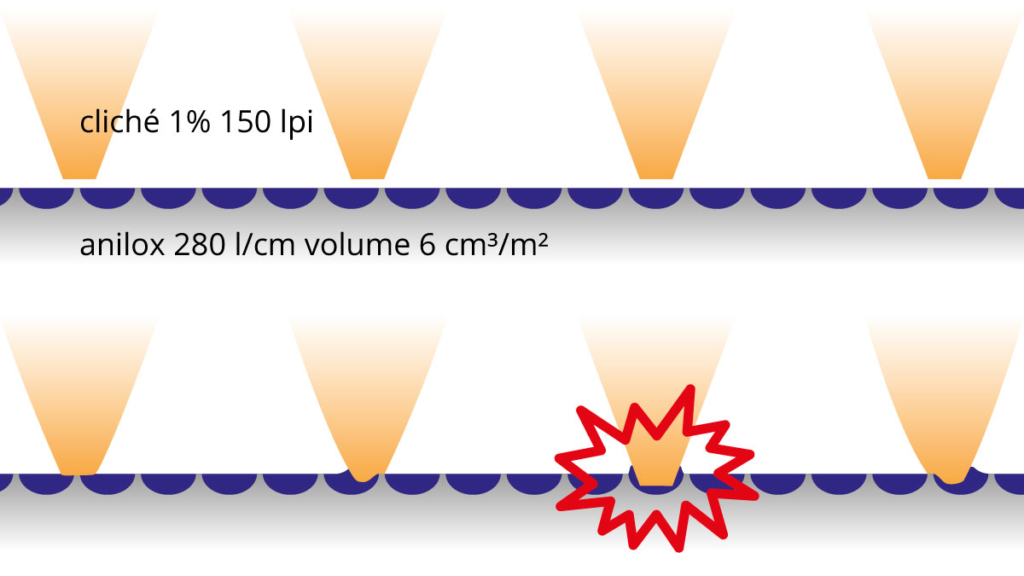

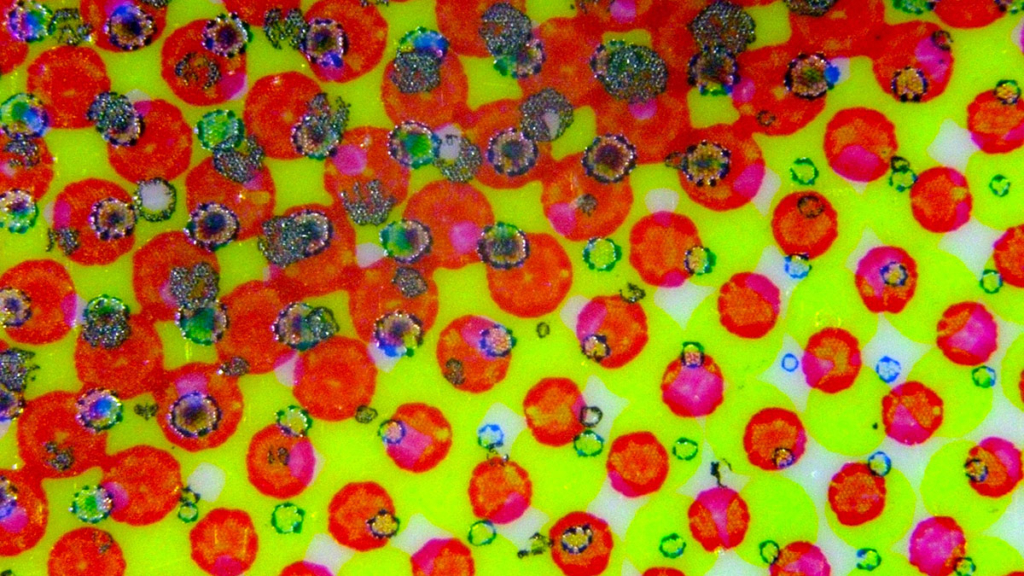

Unfortunately dot dipping does exist, and changing anilox brand won’t heal the problem. We know it is the result of concurring causes that include the size of the engraving cavities on the anilox, the size and the distribution of the plate dots, the impression between plate and anilox resulting from the interference on the nip.

If the diameter of a dot on the plate is smaller than the aperture of the engraving on the anilox roll, the dot could definitely dip in the engraving, and load ink in excess.

“If you can measure it, you can control it”

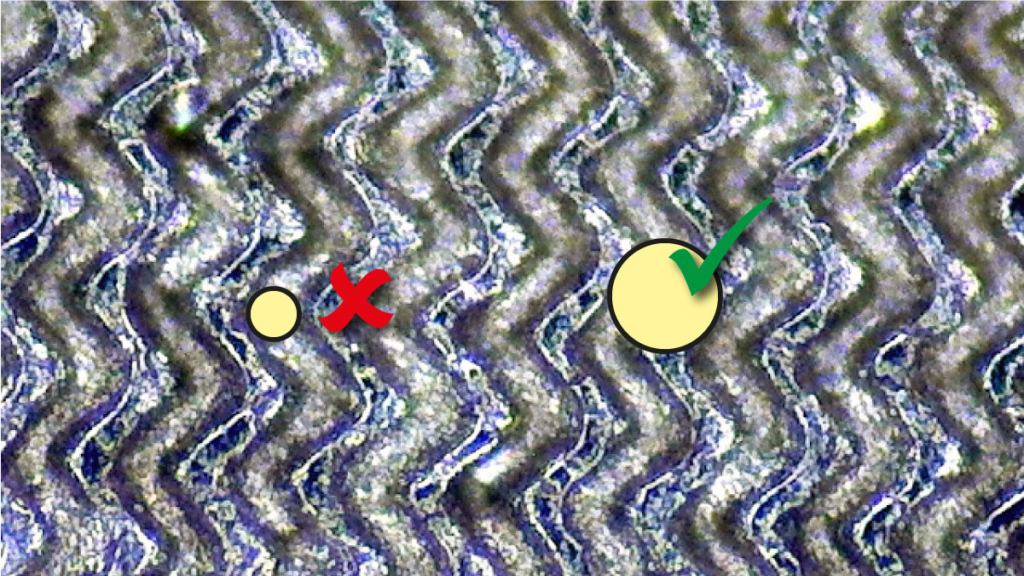

Calculating in advance the ratio between dot sizes and anilox cells opening will allow to use dots with a diameter that is equal or larger than cells openings, and will prevent from dot dipping. If you don’t know the size of your anilox engraving or the size of your plate dots, please measure with a microscope with a proper magnification (>400x): you will understand weather any print defects on highlights are related to dot dipping or other typical causes such as excessive impression, slurring or ink flooding.

Certainly if you over impress the plate ,it would be possible to dot dip

But if properly set this would not happen

Regards