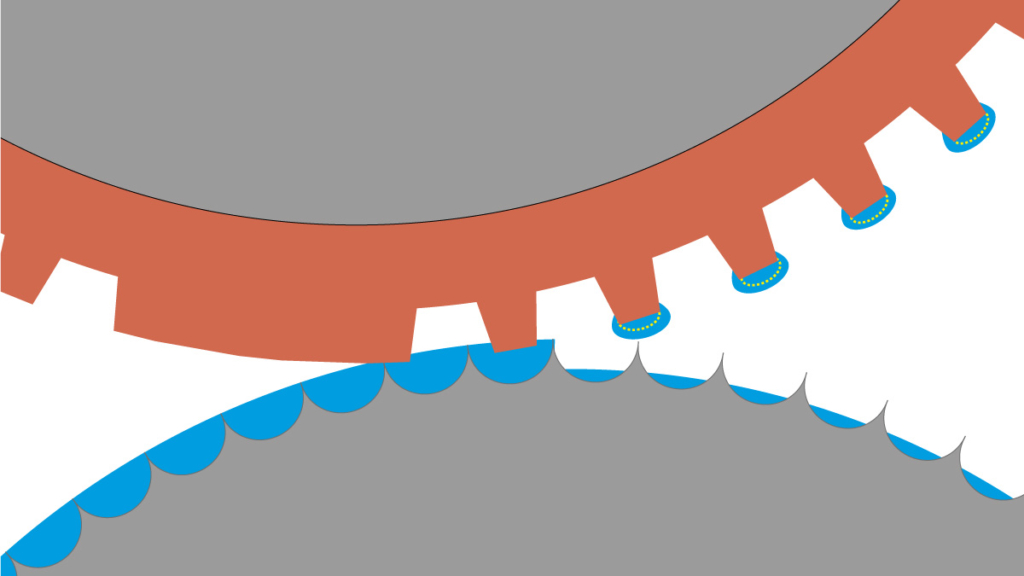

Dot dipping describes the condition whereby the smallest dots on a flexo plate dip into the cells of the anilox roll when forced by the impression between anilox and plate.

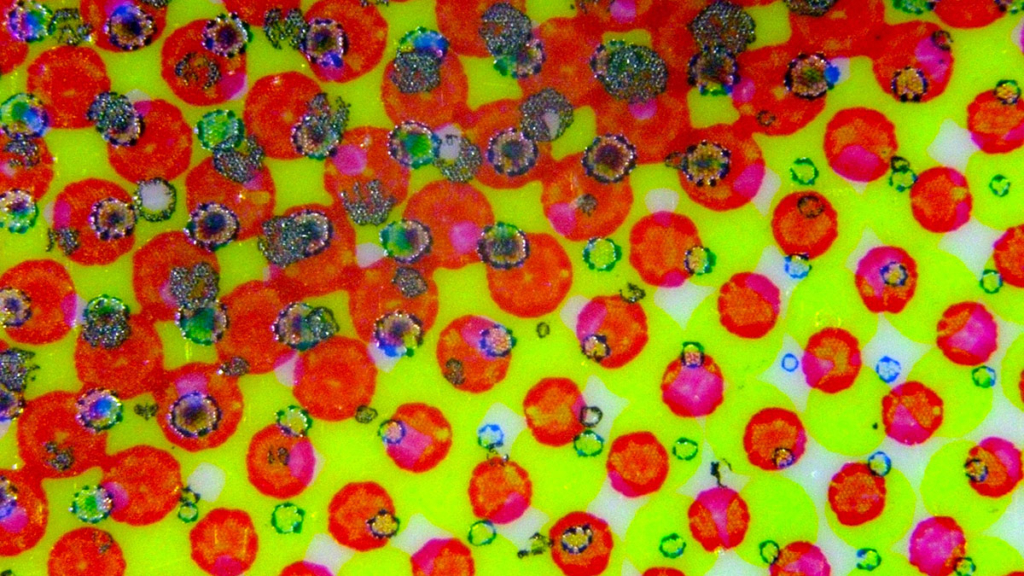

Some dots of the plate, dipping in the cells, will carry more ink than what was expected, resulting in dirty printing in highlights, typically seen as darker thresholds in vignettes fading to zero.

Either the dots on the plate are too small or the cells opening of the anilox roll are too big for such dots.

The choice of plate linescreen and minimum dot size was made without considering the characteristics of the available anilox rolls.

Or, on the other hand, the inventory of anilox rolls for that press was made without considering the tasks associated with the product to be printed.

Use an anilox roll with smaller cells, thus higher linescreen and lower volume.

Reduce the linescreen of the plates, having highlight dots with a slightly larger diameter, or use a hybrid screen and set a minimum diameter of highlight dots to be same or wider than cells openings.

For example, if you want to print a vignette to zero at 120 lpi (48 l/cm), without assigning any minimum dot threshold, your plate will have some dots in highlights with a diameter of ~24 µm or less. If you try to print with an anilox roll having 200 l/cm (~500 lpi), that has a cell opening of ~45 µm, you most likely risk to have smallest dots dipping in anilox cells.

On the other hand, if your products need to be printed at 120 lpi (48 l/cm) with vignettes fading to zero, then you better configure your press with rolls having cells openings of ~24 µm or less: maybe a 360 l/cm or 900 lpi could do).