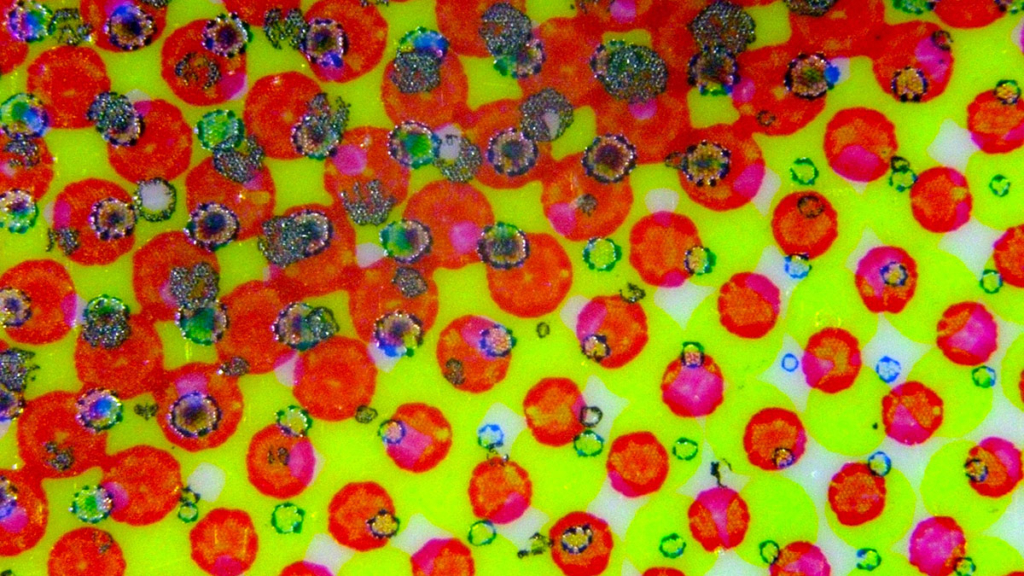

Ink builds around small print elements like dots and small type creating hollow shapes like donuts.

Inked dots perforate ink layers that were printed by previous printing groups.

This happened on external print on plastic film, solvent based inks, flat-top plate, sequence YMCK.

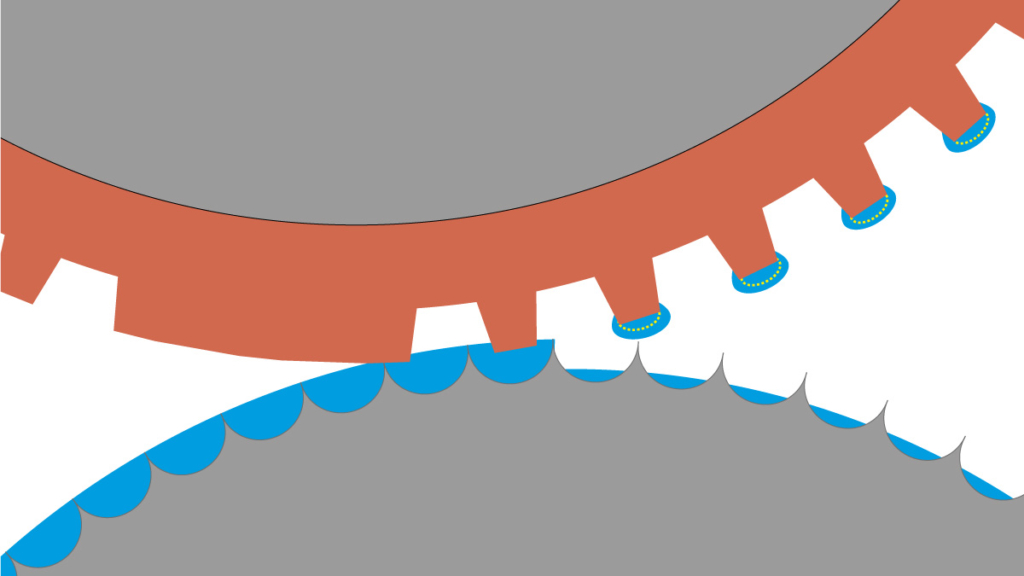

Combined action of excessive impression with high ink volume and low viscosity inks.

Dots overloaded with ink (too high anilox volume) find previous ink layers non properly dried: impression squeezes the ink and spreads around print element edges.

Unstable print condition, inconsistent results.

Review print condition calibration (optimization procedure).

Usa a lower volume anilox

Apply lower impression settings, especially plate to substrate

Increase ink viscosity.