Have you ever wondered why we need to use different screen angles in flexography?

First of all we need to remember that we consider the screen angles when we look at the final printed product, so the parameters we set in the prepress/imaging workflow are meant to obtain the angles as described.

Then we need to consider the origin of such angles and the reason why we set CMYK primary colours on certain angles.

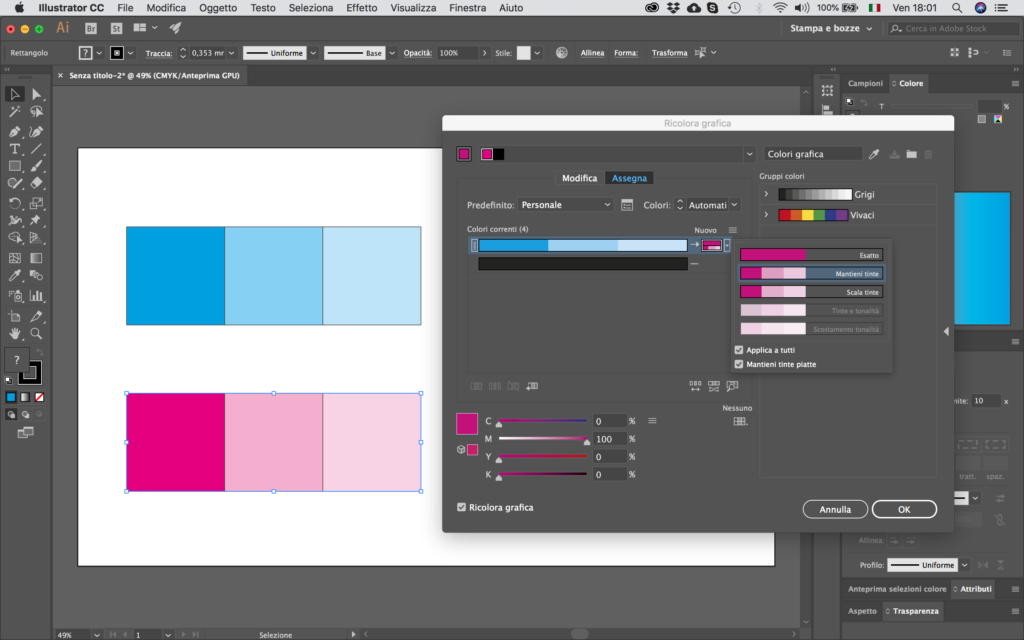

The human eye can better distinguish a repeated pattern made by dots when they lay over an orthogonal structure, thus vertical and horizontal. At the same time, the human eye will be less discriminant if the pattern lays on a 45° angle.

For this reason, earlier screen rosettes printed in offset or letterpress, were made with the darkest colour (black) at 45° and the lightest colour, the one we distinguish less, thus yellow at 90°.

The other two remaining colours will stay 30° apart from the darkest colour: cyan at 15° and magenta at 75°.

When flexography developed into a higher quality printing system, being able to reproduce colour separations, it was necessary to change these angles because the angles of the anilox rolls engravings could interfere and originate a moirée effect on print.

When thinking about the anilox roll engraving angle we shall not forget to consider the bisectors generated in those patterns and avoid them as well: for this reason the screen angles in flexography are rotated -7,5°.

This is supported by ISO 12647-6:2012 – Graphic technology – Process control for the production of half-tone colour separations, proofs and production prints – Part 6: Flexographic printing:

For half-tone dots without a principal axis(*), the nominal difference between the screen angles for cyan, magenta and black shall be 30°, with the screen angle for yellow separated by 15° from another colour. No colour should align with engraving pattern on the anilox roller.

(*) The term “principal axis” refers to elliptical dot screens that feature 2 distinct orthogonal axis and spread over 180°. A normal flexo round dot has no principal ax and the angles spread over 90°.

How can i know the exact angle of a job in cmyk flexo printing. What does different lpi

In anilox mean for. Does the angle changes

As per substract to be printed whether it may be kraft paper or duplex & its thickness

Hello Zakir and thanks for questions.

If you want to know the angles that were used in a printed product, there are specific tools (goniometer/protractor on film) to check directly on printed substrate.

Different lpi on anilox rolls are normally related to different ink volumes required in production, example white ink might require a higher volume than CMYK inks. The angle of anilox roll depends on the engraving geometry that was selected on anilox manufacturing.

Concerning substrate, flexography can print on virtually any type of products with proper selection of compatible inks and plates: kraft paper is normally printed with waterbed inks and the thickness depends on press mechanical specifications.