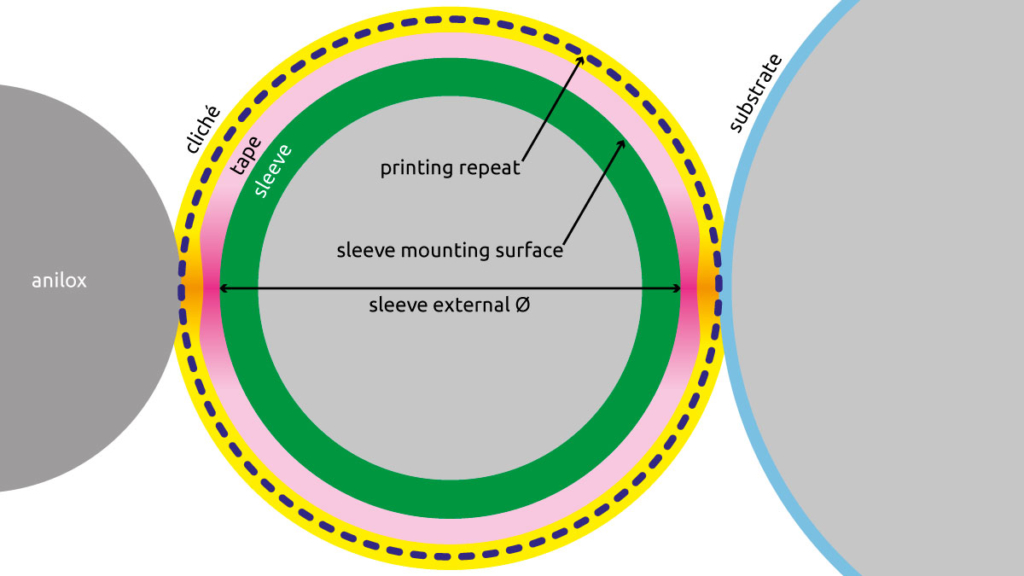

The sustainability of a printed package doesn’t depend only on the type of substrate used: prepress activities and printing conditions play an important role too. In this article, published on Converting magazine, I tried to give some indications to achieve very significant savings in the flexographic process.

You can download the full article with English translation here below (for some unknown reasons the preview shows some errors and blanks in the pages but the PDF download is correct):

Here is a quick link to the thesis of Kai Lankinen, Evaluation of Expanded Gamut Printing in Flexography, that is mentioned in my article.